Bioleaching is a hydrometallurgical process using microorganisms to extract metals from rocks. Even if it is slower than some other chemical leaching technologies, bioleaching offers several advantages compared to conventional metallurgical processes, such as lower energy and chemical consumption, lower CO2 footprint and lower capital and operational costs. Bioleaching has always been a key technology for the treatment of low-grade resources.

It has been applied successfully for more than 40 years to recover copper from low-yield ores, especially in South America, or cobalt from mine tailings in Uganda or in Finland. In the RAWMINA project, bioleaching marks the initial stage of the whole process flowsheet designed to recover critical metals and minerals from Spanish mine tailings. BRGM conducted a bioleaching demonstration at its piloting hall in Orleans, France, and the University of Seville conducted similar research using different microorganisms. The outcomes from both partners were compared in order to support the decision-making process of the project and the process upscaling.

The process started with a journey between Spain and France: several tons of sulfidic tailings were sent from the mine facility to BRGM, where they were prepared for the next steps of the study. Following drying, homogenisation and subdivision in representative samples, the wastes were characterised according to content, mineralogy and particle size, and subjected to numerous experiments. The first step was to check the compatibility of the mining wastes to bioleaching and the ability of the bioleaching microorganisms to use the wastes for growing and self-maintenance. Most bacteria used in bioleaching processes display features that are unique in the world of living organisms:

● They are able to live in very acidic environments.

● They are able to develop in the presence of metals that are very toxic for other life forms.

● They can rely on the carbon dioxide contained in the air for their carbon needs, which means that they do not need any organic carbon source.

These astonishing properties enable them to develop despite the very harsh environment encountered in bioleaching processes. As an example, the bacteria used by BRGM in RAWMINA were progressively adapted in order to function optimally at a pH near 0.9. The concentration of solids in the process pulp is another key parameter greatly impacting the economic viability of the technology. Put simply, higher solid concentrations allow for smaller bioreactors, thus reducing capital costs.

However, increasing the solid concentration may also inhibit the development and the activity of the bacteria. Through expertise developed and effectively applied in several former bioleaching projects, the bacteria used by BRGM in RAWMINA remained strongly active at a solid concentration of 15%, mirroring the conditions applied in current industrial bioleaching operations.

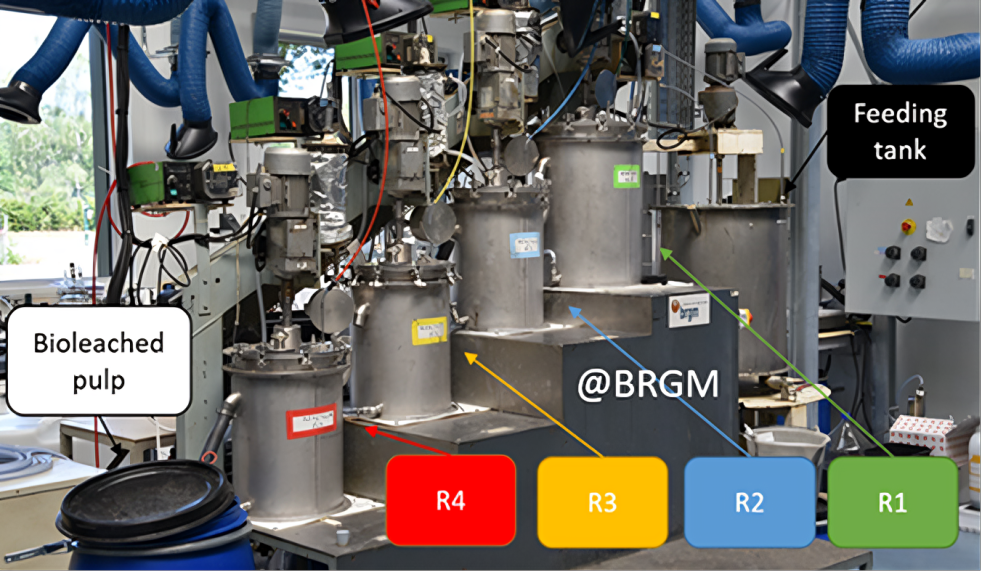

After the selection of the microorganisms and the optimisation of the leaching conditions, a demonstration of the technology was performed in a mini-bioleach plant (with a volume of 114 L) installed in the BRGM piloting hall (see Figure 1). The plant consists of a cascade of 4 bioreactors in series, a primary one of 51 L and three secondary ones of 21 L.

Once inoculated with the selected bacteria, it was fed continuously (24 hours per day, 7 days per week) with the mining wastes, water and some nutrients (K, N, P, Mg) necessary for the effective development of the microorganisms.

Bioleaching pilot at BRGM, France

The bioleaching operation lasted 10 weeks during which 240 kg of material was treated. A team of five researchers and three lab technicians was involved with managing pilot maintenance and monitoring experiments. Every day the team performed several measurements, including physicochemical parameters (pH, redox potential, dissolved oxygen and conductivity), metal concentration, inlet and outlet liquid flows and gas compositions. Regular microbiological analyses were also performed. These data enabled the assessment of bacterial development and activity, as well as process performance.

Particularly noteworthy was the operation’s high metal recovery, with more than 85% of cobalt and copper successfully leached. Another key aspect was the rate of the bio-chemical reactions: the bacterial adaptation procedure promoted a strong and robust activity which enabled similar leaching rates observed in industrial bioleaching applications. The bioleached pulp collected at the outlet of the plant was filtered, and the leach solution containing the metals extracted from the waste was sent to other RAWMINA partners who are now attending to the purification of the targeted metals and the valorisation of the side streams.

The RAWMINA project highlights the significant opportunities that bioleaching presents for the treatment of mine waste and low-grade ores. Through innovative methodologies, the project demonstrates the potential to recover critical metals and minerals from mine tailings, thereby addressing environmental concerns and enhancing resource utilisation. As the mining industry pursues more sustainable practices, bioleaching is emerging as a promising option for transforming waste into valuable resources. Moving forward, continued research and development in bioleaching technologies will further unlock the potential of this process, offering new opportunities for the treatment and valorisation of different types of mine waste on a global scale.

Authors: AG Guezennec, D. Pino-Herrera, F Bodénan