Critical Raw Materials - the Challenge

Since 2011, the European Commission has published a list of CRMs every few years.

In 2020 the most recent list identified 30 materials that fulfilled their definition.

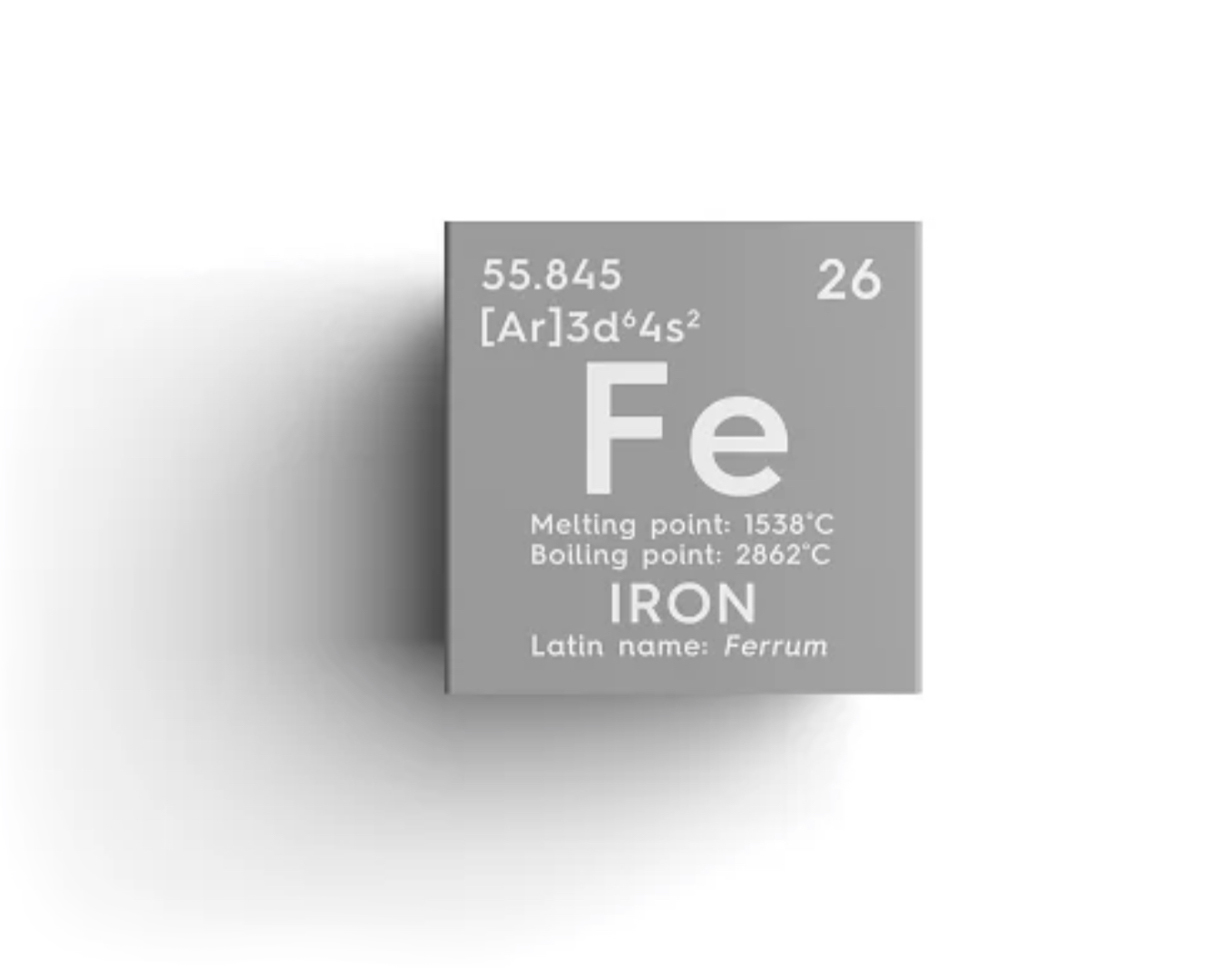

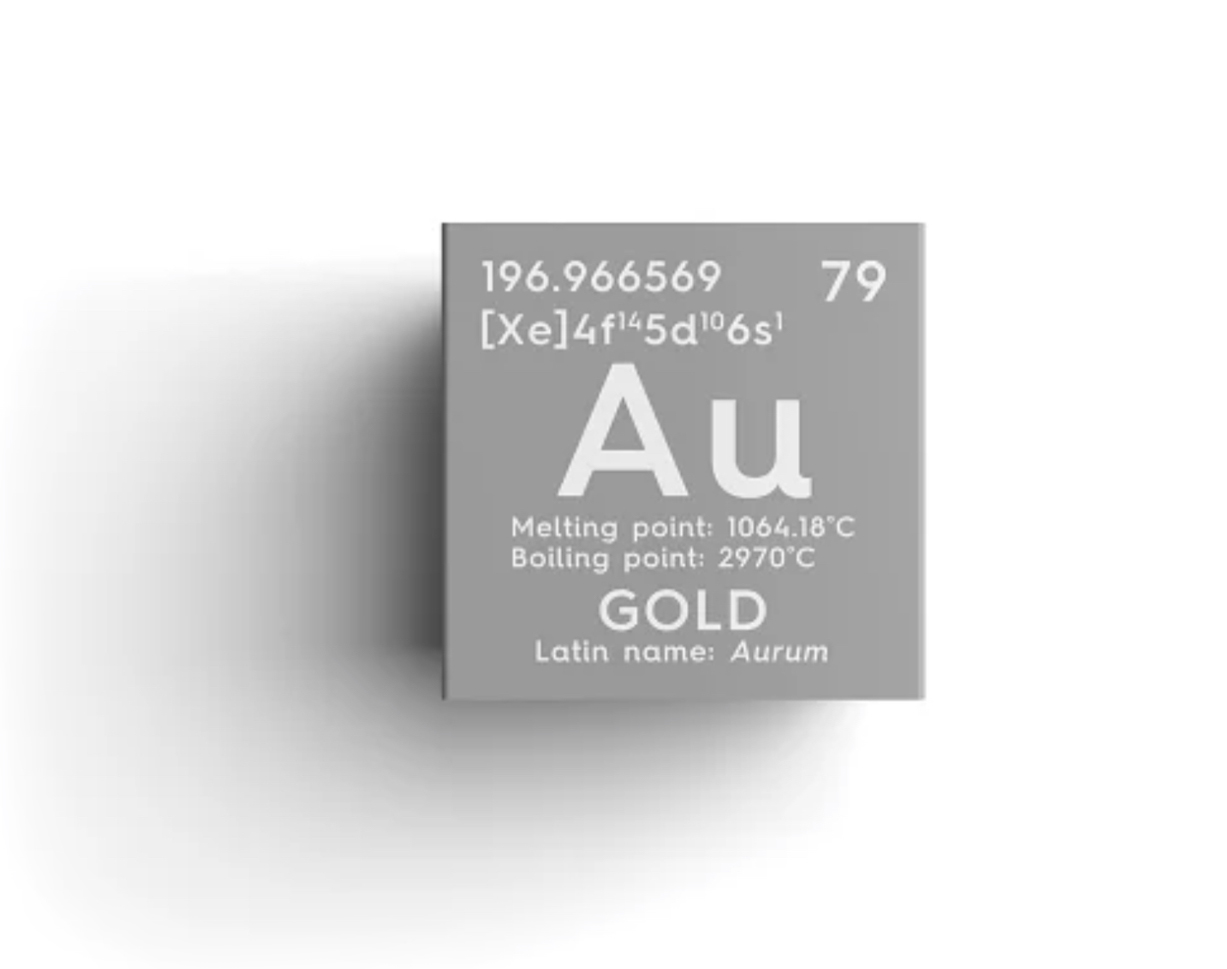

Most of the CRMs are metals. However, silicon, several metal ores and other naturally occurring minerals and materials (e.g. graphite and natural rubber) are also listed.

"Critical" does not necessarily mean scarce.

CRMs are listed because they:

The EU’s one-sided dependencies in the supply of resources considered “rare” and “critical” are a growing concern.

Policy-makers at all levels are thinking about the potential effects of losing access to “Critical Raw Materials” (CRM) – metals and minerals that are used in countless everyday and industrial products.

Major changes in the materials we need are also expected as we switch to digital and sustainable (green) technologies. Solar panels, batteries for electric vehicles, circuitry for drones and other mobile devices all demand an increased supply of CRMs.

Industrial adaptation and trade agreements will be part of the solution. However, we must also develop new, innovative technologies that help alleviate supply issues, and reduce future dependencies.

Extractive waste – a problem or an opportunity?

While there is negligible mining of CRMs in Europe (a contributing factor to the definition of each CRM), there are many active and abandoned mines for other minerals, such as copper and zinc.

These mines, sometimes active for more than 100 years, have been discarding large amounts of material not considered valuable – “extractive waste”. This is a huge environmental issue; toxic, acidic solid waste and lagoons, but also an opportunity as the ‘waste’ may contain valuable CRM to be recovered.

The Circular Economy Principles

“Circular economy” has become the buzzword for sustainable practices at a national and global scale. Achieving “circularity” is based on three principles, driven by design:

“Circularity” decouples economic activity from the consumption of finite resources; a resilient system that is good for business, people and the environment. In the ultimate dream of the circular economy, there would be no more mining – we have all the resources we need already in circulation.

There are many challenges yet to be addressed in achieving this vision, and growing demands from the green and digital transitions that still need to be met. As address these, there will be opportunities along the way to accelerate progress on individual elements – low-hanging fruit – that we should grasp.

Through Horizon2020, addressing the CRM strategic needs identified by policy-makers at the European Commission, RAWMINA will:

Realise a new source of CRMs, readily available from what was previously considered waste, from active and abandoned mines

Adding new treatments and conversions always has the potential to create further environmental impact. This must be balanced against the current situation of directing waste to landfills. In RAWMINA, we will perform a life-cycle assessment on each part of our pilot demonstration of mine-waste valorisation, and always target low-energy, low-impact processes.